Hot news

Contact information

- phone:86-714-6393188

- Telephone:86-714-6393188

- Q Q:297705516

- Email:hongda@hdeko.com

- Address:Machinery Industrial Park, Huangjinshan Development Zone, Huangshi City, Hubei Province

Methods and techniques for solving the difficult problem of

Source: Pubdate:2020-09-28 11:42; Click:

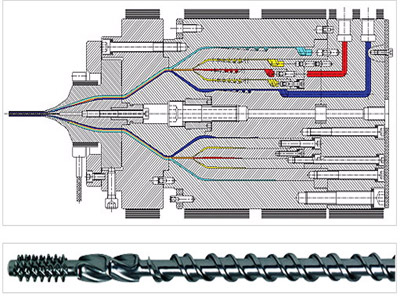

Die biting phenomenon is also known as die discharge, die penetration, fouling, is a common problem in the extrusion process. This kind of failure can cause many kinds of product defects, such as the surface material shortage of extrusion products, the interruption of processing flow and the complete cracking of products. When encountering this kind of trouble problem, the processing factory often has to spend time and manpower to remove the trouble, but as for how to avoid this kind of trouble problem, there is no way and countermeasure.

When the extrusion line is running, the die with simple shape may be kept clean. If the angle of pulling the extrudate away from the die is changed, the layout of the infiltrated material on the die can be changed and it can be cleaned easily. The phenomenon of die biting can also be consciously transferred to the extrusion products, further away from the production equipment. For example, when processing extruded sheet, the mechanical automatic scraper can be installed to avoid the failure of clamping die.

However, most processing plants usually have to interrupt the operation of the production line to eliminate the biting failure, which is not cost-effective in economy. After the die is cleaned, the outer surface of the die is coated with release agent or silicone, which can reduce the probability of biting and prolong the interval period of cleaning die head. A slight reduction in the production rate can also reduce the occurrence of die biting, but this will affect the yield. All of these solutions are not the key. There's a better way to solve this problem so that you can understand what's causing biting.

The resin flows slowly in the die head and accelerates suddenly when it is extruded to the die mouth. This accelerated motion produces a stress in the melt. Under the action of stress, low molecular weight polymer components separate from other components in the melt and accumulate in the die. The solution is to reduce the stress at the die or to reduce the separation tendency of various components in the melt. These solutions include changing process conditions, raw materials and dies.